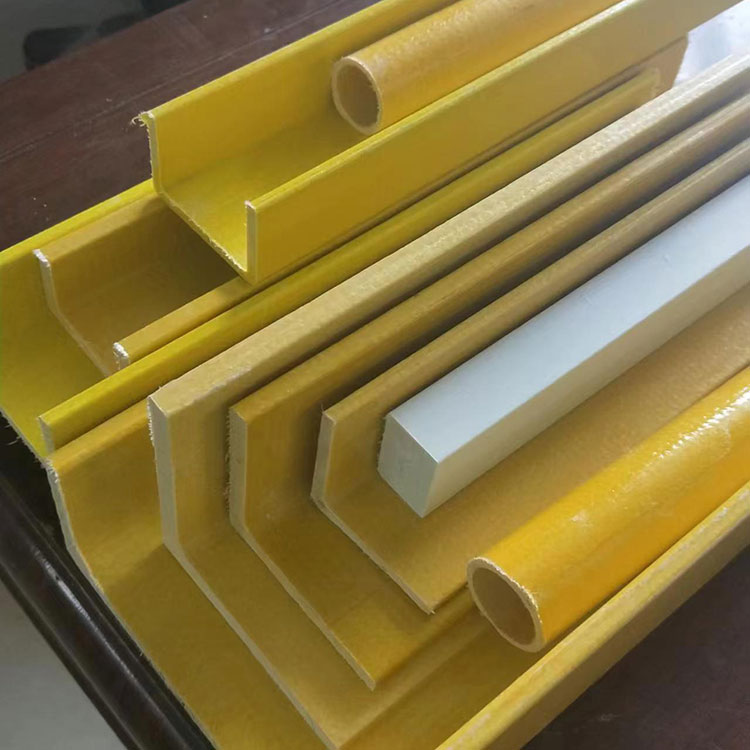

Pultruded FRP Profiles are composite material profile made through pultrusion process.

Hebei Tengjun Pultruded FRP Profiles shape:

1. Square: With straight edges and four right angles, it is often used for structural supports and frames.

2. Round: cylindrical shape, can be used for pipes, railings, etc.

3. Rectangle: Similar to a square, but the edges are not necessarily right angles.

4. Triangle: used for specific structural needs, such as trusses.

5. T-shape: Has a horizontal part and a vertical part for connection and support.

6. L-shaped: Can be used for corner connections or building specific structures.

7. I-shaped: The middle part is thicker and the sides are thinner, providing better strength.

8. Groove shape: It has a concave shape and can be used to install and fix other components.

9. Special shapes: Special shapes customized according to specific needs to meet special design requirements.

These shapes can be achieved by adjusting the mold. Different shapes are suitable for different application scenarios and meet various structural and functional needs.

Advantages of Pultruded FRP Profiles:

1. High strength: excellent load-bearing capacity.

2. Corrosion resistance: It can resist the erosion of various chemical substances.

3. Good insulation: suitable for electric power field.

4. Light weight: easy to install and transport.

5. Aging resistance: long service life.

Product selling points:

1. Customizability: to meet various special needs.

2. Excellent performance: performs well in a variety of environments.

3. High cost-effectiveness: high overall cost performance.

Suitable for occasions:

1. Building structure: used for support and reinforcement.

2. Chemical equipment: The advantage of corrosion resistance makes it suitable for the chemical industry.

3. Electrical facilities: good insulation performance.

4. Transportation: It has applications in vehicles, rail transportation, etc.

5. Environmental protection equipment: Corrosion resistance makes it widely used in the field of environmental protection.

6. Fence guardrail: high strength, safe and reliable.

Production process of Pultruded FRP Profiles:

1. First, mix glass fiber bundles, resin and other raw materials according to a certain proportion.

2. Then, the mixed material is passed through the pultrusion equipment, and gradually formed into shape under the action of high temperature and high pressure.

3. During the pultrusion process, the material will pass through the mold to form profiles with specific shapes and sizes.

4. Finally, after cooling and solidification, fiberglass pultruded profiles with high strength, corrosion resistance and other excellent properties are obtained.

5. The entire production process is highly automated, which can ensure product quality and stability.

Pultruded FRP Profiles have a variety of excellent properties and are used in a wide range of fields, including but not limited to the following fields:

1. Construction industry: used as supports, fences, handrails, etc. for building structures.

2. Transportation: used to manufacture vehicle parts, rail transit facilities, etc.

3. Electric power industry: can be used in power towers, insulation components, etc.

4. Chemical industry: suitable for anti-corrosion parts of chemical equipment.

5. Environmental protection field: such as waste gas treatment equipment, sewage treatment equipment, etc.

6. Communications industry: manufacturing communications towers, radomes, etc.

7. Agricultural sector: architecture for agricultural facilities.

8. Leisure and entertainment: facilities such as parks and playgrounds.

9. Marine engineering: marine platforms, ship parts, etc.

10. Municipal projects: road guardrails, billboards, etc.

11. High strength and rigidity, able to withstand larger loads.

12. Corrosion-resistant, suitable for various environments.

13. Light weight, easy to install and transport.

14. Good insulation performance.

15. The color can be customized to meet aesthetic requirements.